How LNG Tankers Are Unloaded at a Regasification Terminal

For operators on the ground and engineers, tanker unloading is not just a routine task—it is often the most mentally demanding and high-risk activity in daily LNG operations. The LNG truck unloading process is a critical operation at LNG and LCNG stations, requiring strict safety and operational procedures. Liquefied Natural Gas (LNG) is widely transported by cryogenic trucks from terminals to LCNG stations, industries, and power plants. Once the LNG truck reaches its destination, the unloading process must be done carefully to ensure safety and prevent LNG loss.

In this article, we explain the LNG truck unloading process step-by-step, in the easiest way possible.

What Is LNG Truck Unloading..?

LNG truck unloading is the process of transferring LNG from a cryogenic road tanker to a storage tank or pipeline at an LNG station or facility. Since LNG is stored at –162°C, special procedures and equipment are required.

Main Equipment Used During LNG Unloading

Before unloading starts, the following equipment is used:

- Cryogenic LNG tanker truck

- LNG storage tank

- Cryogenic hoses (suction & return)

- Unloading pump (truck-mounted or station pump)

- Emergency shut-down system (ESD)

Step-by-Step LNG Truck Unloading Process

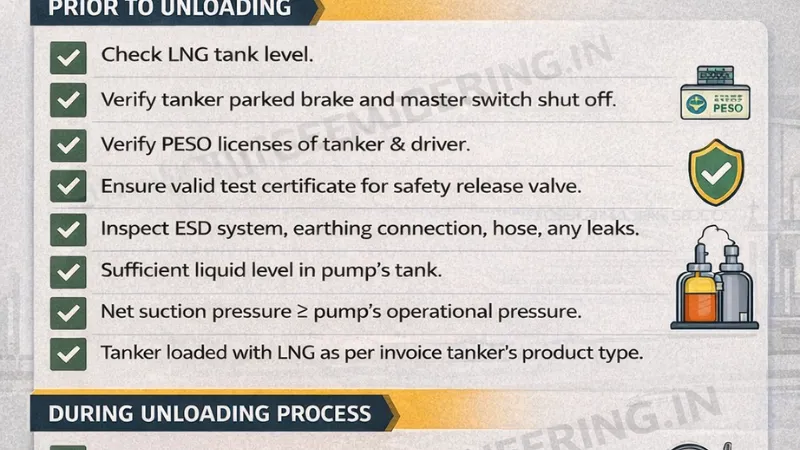

Step 1: Truck Arrival and Safety Checks

- The LNG truck is parked at the designated unloading bay

- Wheel chocks are applied to prevent movement

- The grounding cable is connected

- A safety checklist is done for leaks or damage

- Ensure to kept a fire extinguisher nearby

Operational practices at LNG and LCNG stations are governed by standards issued by the PNGRB, which regulates city gas distribution and LNG handling infrastructure in India.

Step 2: Connection of Unloading Hoses

- Remove suction and return dummy flanges of lng truck

- A cryogenic liquid hose is connected between truck and storage tank

- The vapour return hose is connected to balance pressure

- All connections are double-checked for tight sealing, which is done using non-sparkable spanners

- A small amount of LNG is slowly passed through the hoses

- This cools down the pipes and prevents thermal shock

- Boil-off gas generated during cool-down is returned to the tanker through return hose

- Make sure tanker pressure under the limit.

Step 4: Start of LNG Unloading

- Increase the tanker pressure manually by opening the pressure-building coil

- Monitor the pressure on the tanker pressure gauge

- Raise the pressure to about 4.5 bar

This pressure is needed to ensure enough LNG reaches the pump suction head

- The unloading pump is started, and the open discharge valve is opened gradually, and at the same time the return valve is slowly closed.

- LNG flows from the truck to the storage tank

- Pressure and temperature are continuously monitored using SCADA.

Step 6: Completion of LNG Transfer

- Once the required amount is transferred, pump is automatically stopped.

- Remaining LNG in hoses is drained or vaporised.

- Valves are closed carefully

LNG quantity is measured using different units like kg, SCM, and MMBtu. We have explained all units used in LNG operations in a separate article.

Step 7: Hose Disconnection and Truck Departure

- Hoses are safely disconnected

- Protective caps are fitted

- A safety check is done

- The truck is cleared to leave the facility

Safety Measures During LNG Unloading

Safety is the top priority during LNG unloading. Key safety practices include:

- Continuous gas detection

- suction, discharge temperature and pressure are always monitored

- Emergency shut-down systems

- Trained operators only

- Fire-fighting equipment on standby

- No ignition sources nearby

Common Problems During LNG Unloading

Some challenges that may occur include:

- Excessive boil-off gas generation

- Hose frosting due to low temperature

- Pressure imbalance

- Pump failure or valve malfunction, usually due to cavitation

Proper procedures and trained operators help avoid these issues.

Why Proper LNG Unloading Is Important

Correct unloading ensures:

- Safe handling of LNG

- No product loss

- Protection of equipment

- Smooth operation of LNG stations

Conclusion

– Usually, an inlet SOV is installed between the storage tank and the unloading pump to control LNG flow. A mass flow meter (MFM) is also provided to measure the liquid flow rate and total quantity unloaded. The unloaded LNG is transferred directly to the cryogenic LNG storage tank operation system.

– During unloading, all operating parameters, such as pressure, temperature, flow, and valve status, are continuously monitored through the SCADA system from the control room to ensure safe and smooth operation.

The LNG truck unloading process is a carefully controlled operation designed to safely transfer LNG at extremely low temperatures. By following step-by-step procedures and strict safety rules, LNG can be unloaded efficiently and safely. Understanding this process is essential for anyone working with or learning about LNG infrastructure.

## FAQs on LNG tanker unloading

Q: How long does LNG tanker unloading take?

LNG tanker unloading typically takes 1 to 3 hours, depending on whether it is 15 MT, 17 MT or higher, depending on the vessel size, transfer rate, terminal design, and operational conditions. Large LNG Tankers may require additional time for pre-unloading safety checks, cool-down, and post-unloading procedures.

Q: What safety systems are used during LNG unloading?

Multiple safety systems are in place during LNG unloading, including interlock systems, safety alarms, flame detectors, gas detectors with predefined trip limits, and emergency shutdown (ESD) systems. Fire protection equipment such as 50-kg and above fire extinguishers, firefighting lines kept pressurised with packed water, and fire hydrants are always maintained in a ready condition throughout unloading operations.

Q: Who controls LNG unloading operations?

LNG unloading operations are controlled by experienced operators under the supervision of the station or terminal supervisor. All activities are carried out in coordination with the ship’s crew, following approved operating procedures and safety protocols.

4 thoughts on “How LNG Tankers Are Unloaded at a Regasification Terminal”